-++- ELECTRON

Since 1998, active in 47 countries (2021)

Electron has been developing and producing powder coating equipments completely in-house since 2017.

Complex automatic powder coating systems have been delivered turnkey worldwide since 1998 !

Electron

- Experience as a manufacturer since 1998

- High production capacity

- short delivery time

- Fair prices also for spare parts

- Excellent trained employees and engineers

- Research & development

- Certified worldwide

- All from a single source

Investments

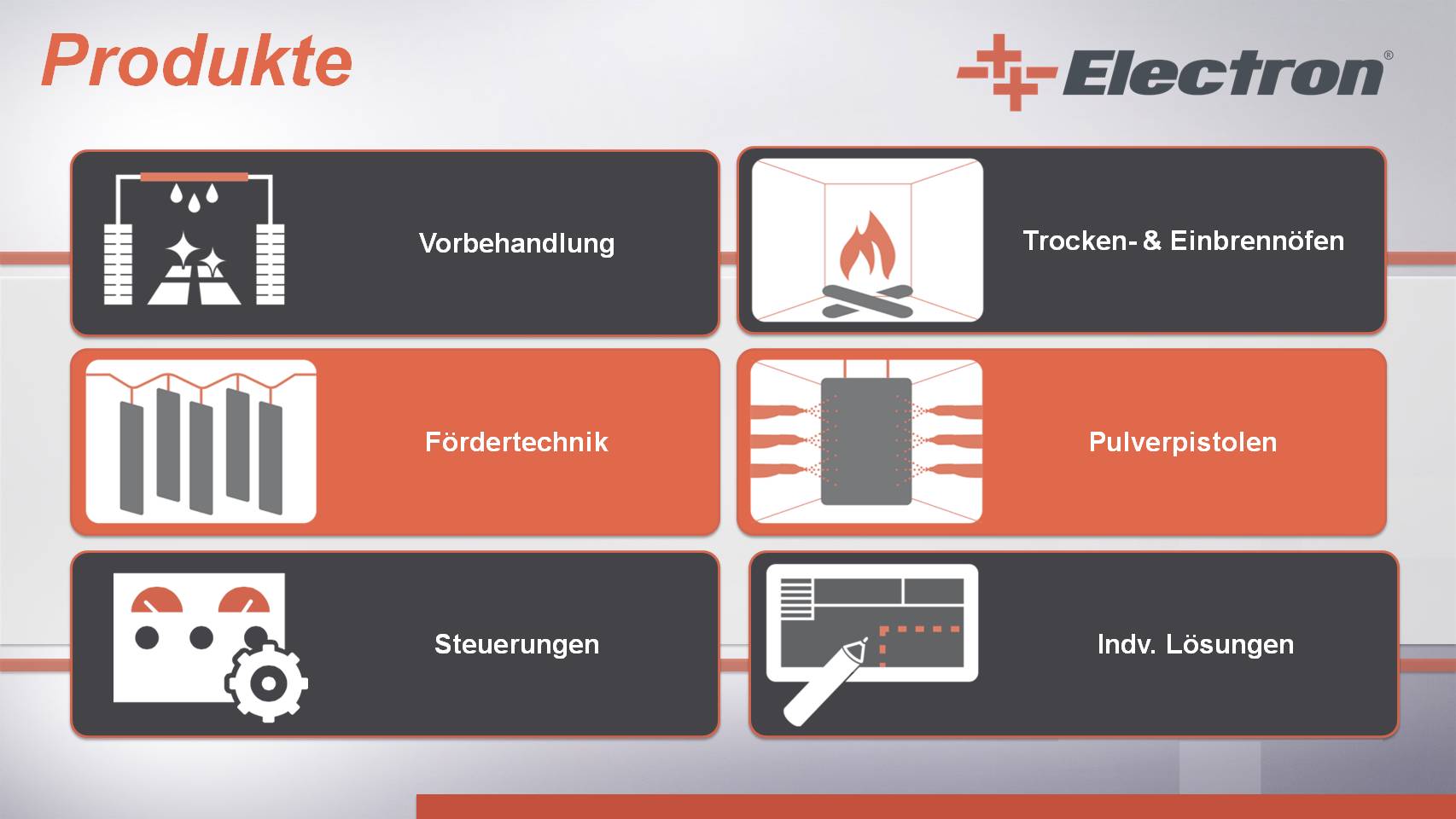

Pretreatment

• Nano technology (Oxsilan, phosphating

• Degreasing and pickling

• Iron and zinc phosphating lines

• Without chrome

• Spraying & immersion pretreatment lines

• Savings in chemical and water consumption

Conveyor systems

• Power & Free or Axial

• Automatic or manual

• Optimal solutions according to customer requirements

• High quality standards

Cabins

• Cyclone or filter with recovery

• Made of plastic or steel

• Quick color change • Low-

noise fans

Powder ovens

• Subsidized or box-shaped designs

• Tunnel, U-Turn or special designs •

Energy-efficient and productive

• Perfect insulation and minimal heat loss

• Homogeneous air distribution

• Precise technology & intelligent solutions

Special solutions

Contact us !

Control systems

• Simple and understandable operation

• Data and history can be called up

• Energy saving functions

• Secure backup

• Remote maintenance

Automatic coating

• Quick change of operation with pre-programmable option settings

• Automatic selection of stroke and speed

• User-friendly touchscreen panel

• 99 recipes. Last working time and

• The entire working time can be saved

• PLC-controlled lifting devices

Hubgeräte

• Perfect results with uniform layer thickness

• Accelerated production

• Perfectly synchronized with lifting devices

• Central powder feed container with powder pumps

• Jerk-free, fast and precise movement for even coating

• Reduced powder consumption

Professional service - turnkey delivery