Heating :

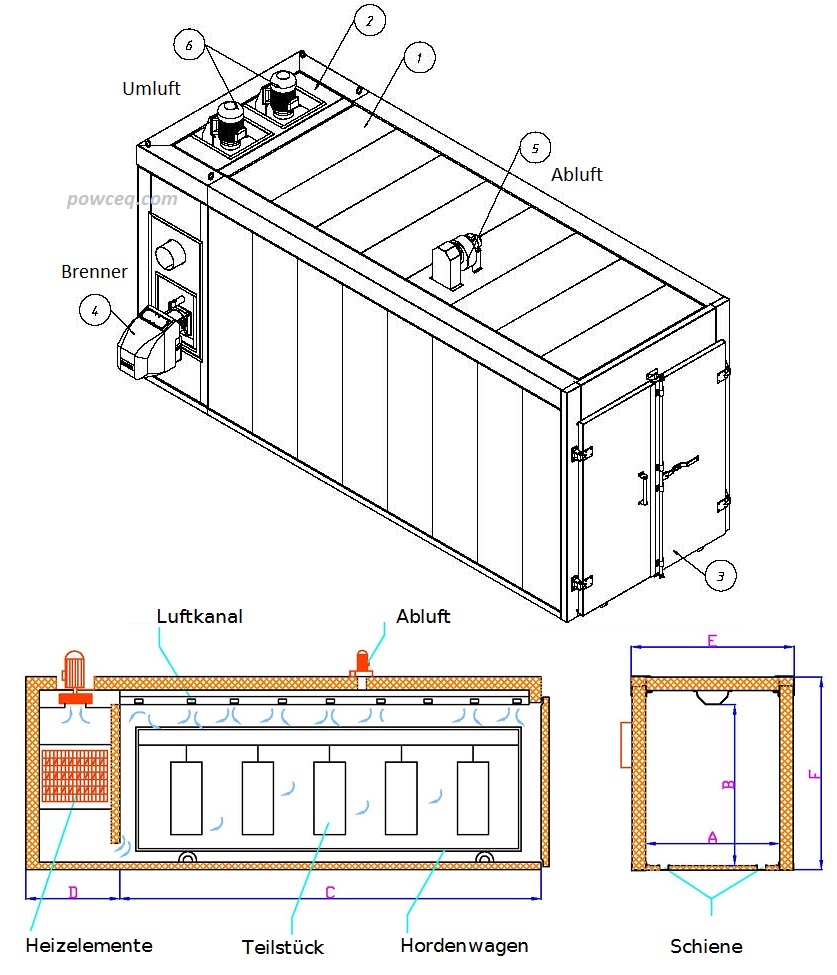

Electrically or with gas / oil burner

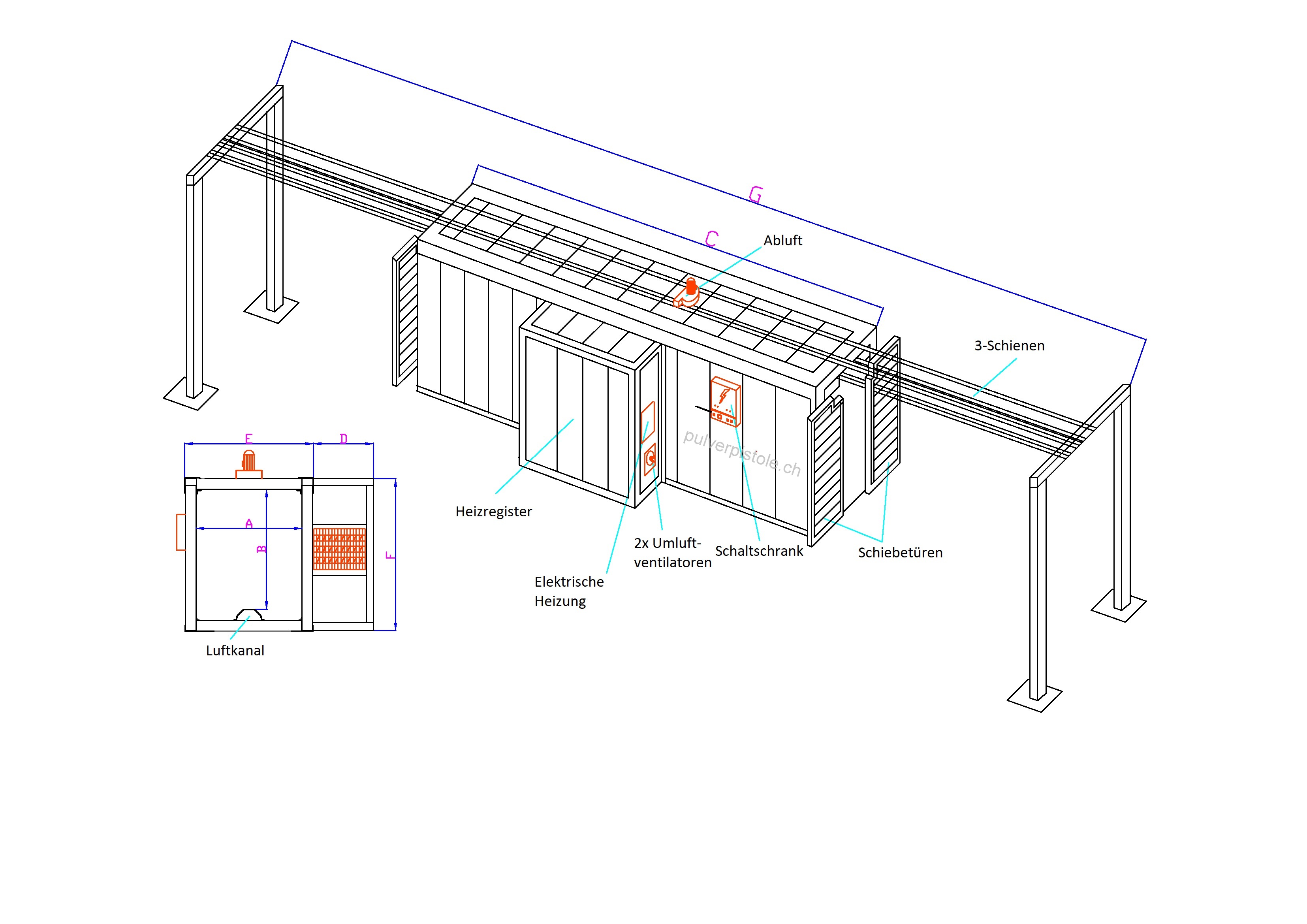

Convection oven, several fans

Homogeneous air distribution (most important!)

Separating doors, sliding doors, folding doors on both sides

Rails, beams, all variants available.

Delivery time only 8 weeks!

Pre-assembled

Dimensions inside

| Type | A width | B height | C depth |

| EL10 | 1 | 1 | 1 |

| EL12 | 1 | 1,2 | 1,5 |

| EL15 | 1,2 | 1,5 | 1,5 |

| EL20 | 1,5m | 1,8m | 2 |

| EL25 | From a depth of 2m | same W x H | 2,5 |

| EL30 | 3 | ||

| EL40 | 4 | ||

| EL50 | 5 | ||

| EL60 | 6 | ||

| EL70 | 7m |

Or ask for your desired size!

e.g. inside 7 x 2.5 x 3 m

Up to 200 ° C or 450 ° C

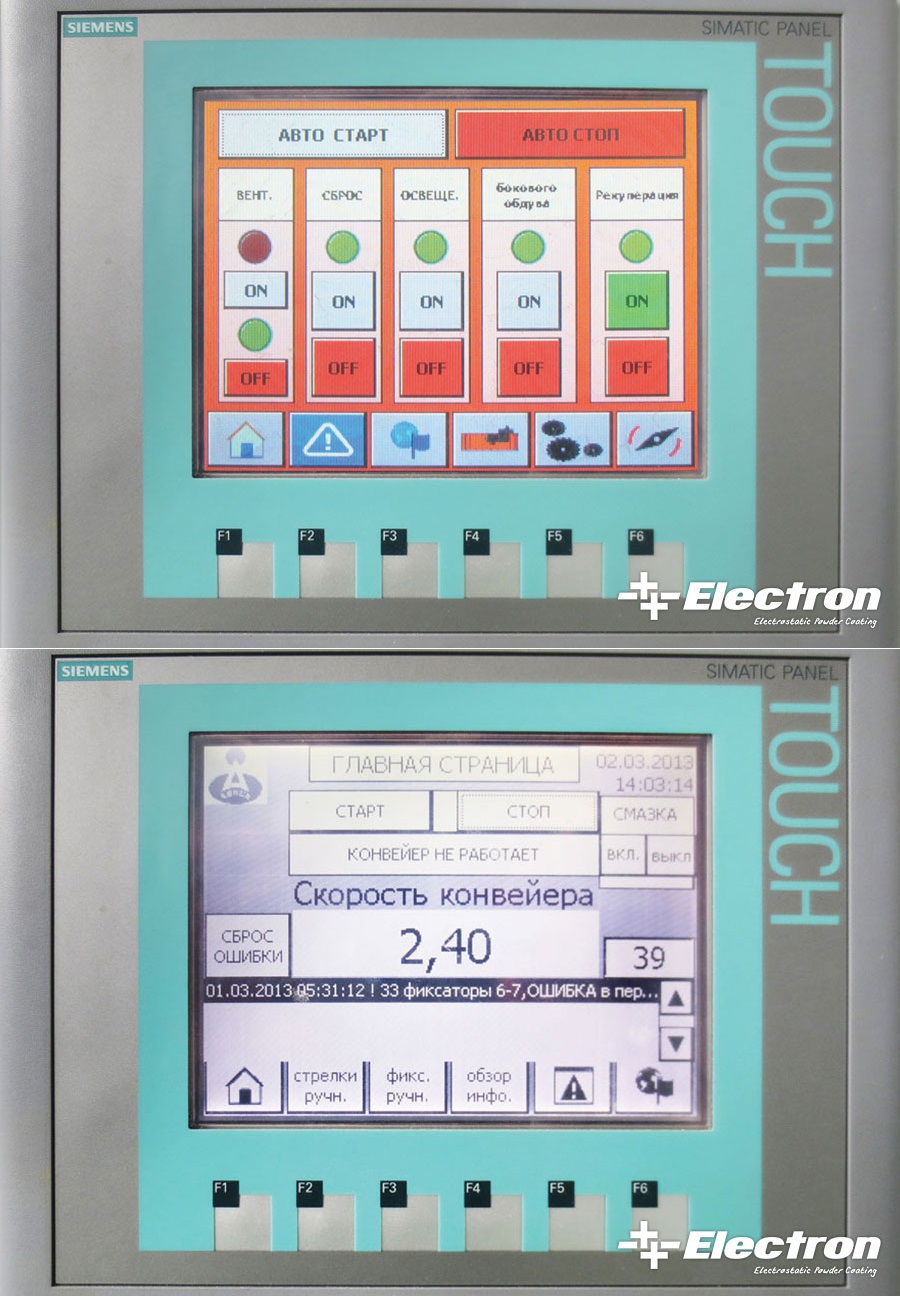

Control: analog or digital

Some variations of kiln curing

The smallest - 1.1m

For 6x rims

Within 7 x 1.5 x 1.8 m

4m rear heating register

4m side view

Double doors

For trolleys

With dividing doors

Larger and special construction powder furnaces

5x rails

Semi-car. Conveyor system

Heavy parts

Conveyor ovens

4m special construction / rack trolley

Chain conveyor / sliding doors

Electrically heated

Continuous furnace

Traverses as desired, manually or semi-automatically

We offer complete solutions from a single source! Turnkey

- Powder booths with filters or Zykon

- Dryers and baking ovens, conveyor track

- Manual systems for powder coating

Upon request via contact, we will be happy to send detailed PDFs.

Powder gun powder booth powder systems

Katalog

Katalog